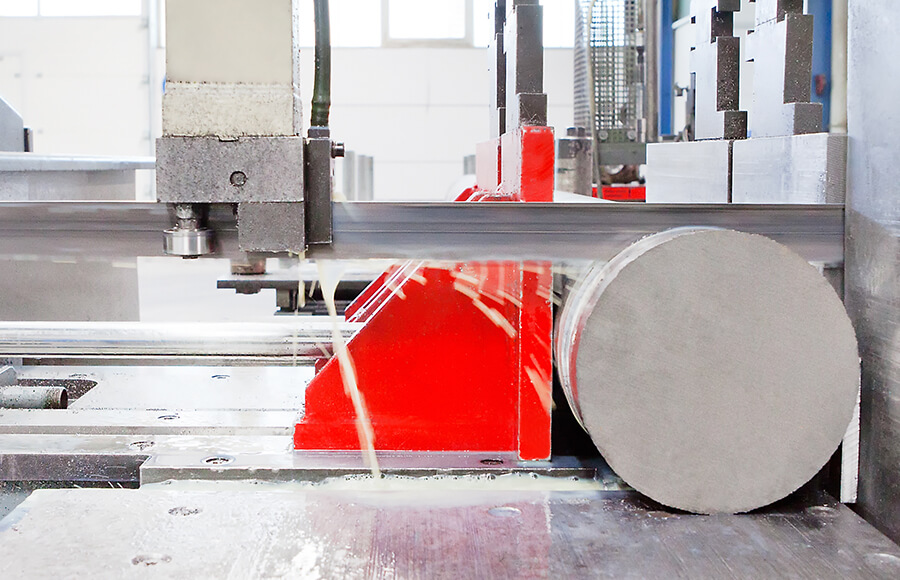

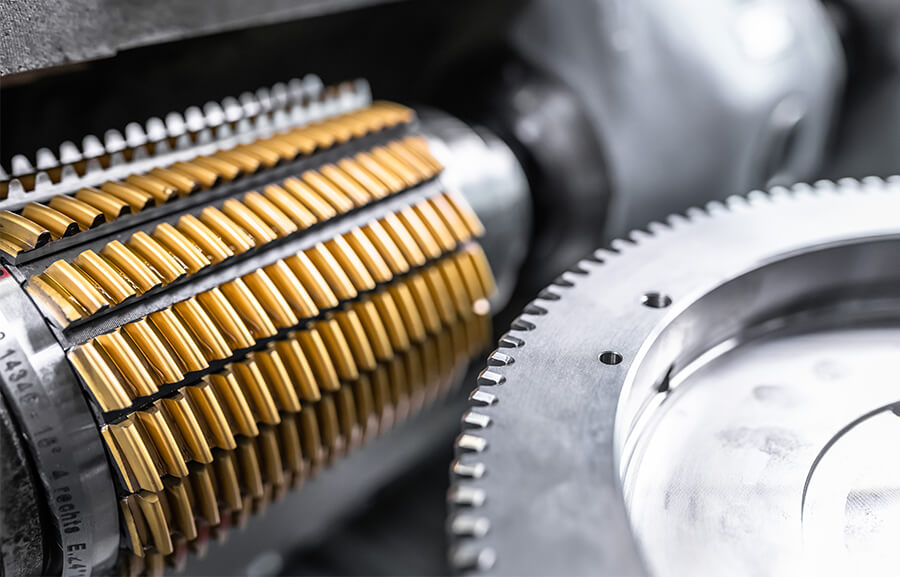

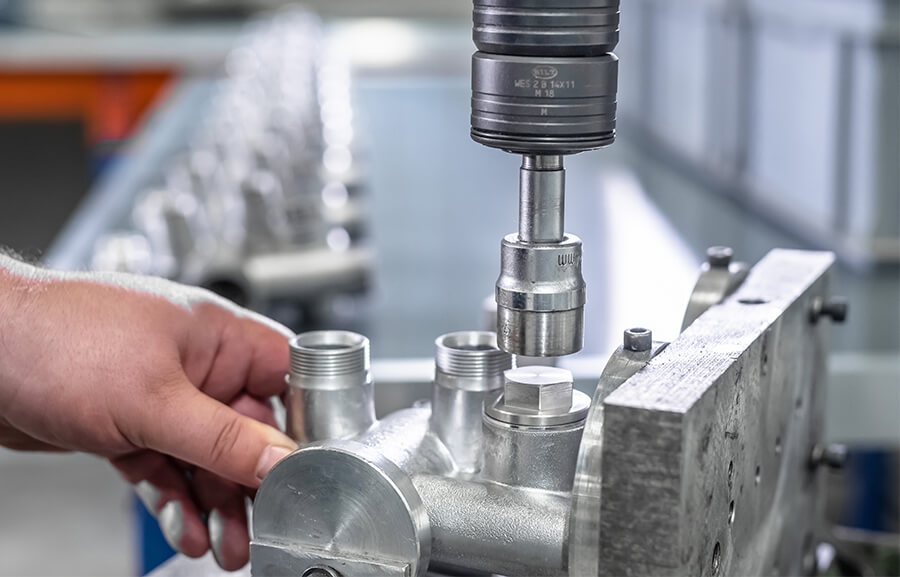

Cutting to length

Our cutting machines allow us to perform saw cuts for chuck parts based on bars. These semi-finished products, made from spheroidal casting, heat-treated steel and case-hardened steel or wrought aluminium alloy are then fed to the relevant turning or milling process.